The barriers to entry of a new -packaged product have been lowered since the pandemic but it’s more challenging than ever to develop products that sell. With 150,000 new food and beverage products entering the market worldwide this year, a quick look at one way to reduce the stress on culinary and product development teams is a worthwhile pursuit.

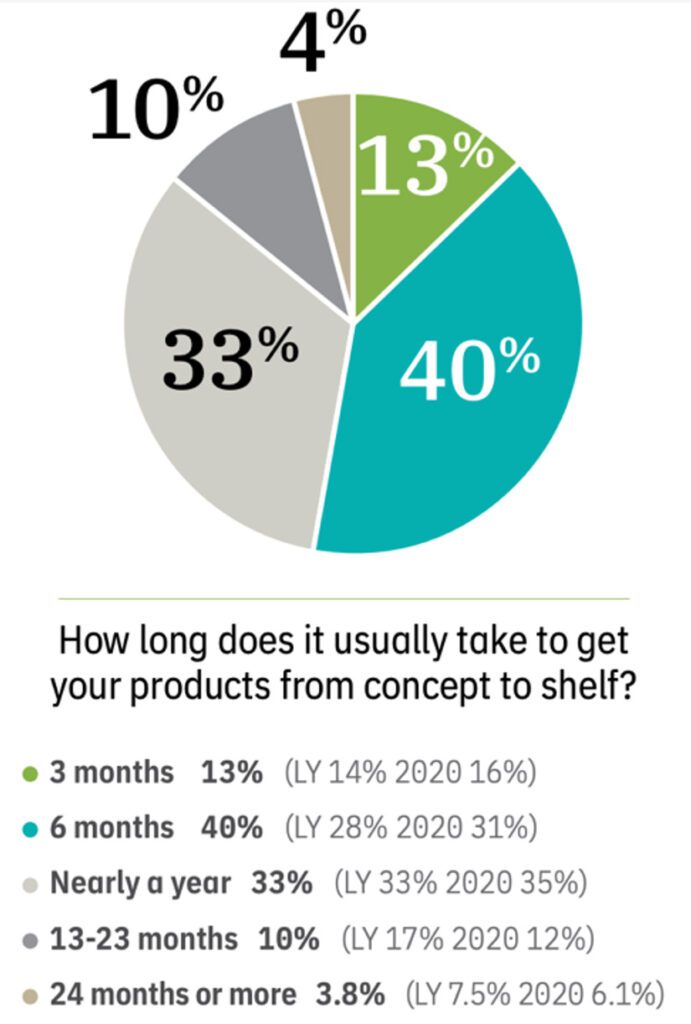

One driver of easy fixes among product development teams is the time required to bring a new product from a concept to the shelf. The latest survey of R&D teams found that more products are being brought to market in 6 months (now 40%, up from 28% just a year ago).

40% of new food products hit store shelves just six months from its initial concept.

This acceleration in bringing products to market has a quarter of R&D teams surveyed* including suppliers as part of the team. Butterball®Farms has been busy advising and bringing solutions to R&D teams nationwide for easing the development process with flavored dollop technology.

Bagged proteins and vegetables are most used to incorporate Butterball Farms flavored dollop technology.

“Imparting flavor through flavored butter dollops is helping reduce product development times by months for our clients,” says Lucia Falek, Vice-President of Development and Quality Systems at Butterball Farms. “Once we’ve aligned on the flavor and its for the intended protein or vegetable, many large food manufacturers utilize our pre-portioned dollops or medallions to automate their process for greater efficiency. Our capabilities include individually wrapped dollops thatcan be printed with brand or allergen information.” The company can also provide specially formulated sauces, gravies, and glazes to go into frozen and refrigerated products.

Dollops and medallions can be individually wrapped, especially useful in prepared trays with proteins.

“Food processors are interested in incorporating trending flavors quickly,” says Falek. “Most recently, the requests involve sauce flavors, like a BBQ or wing sauce or hot honey. We’re likewise seeing interest in our ability to incorporate larger particulates in our dollops or medallions, such as country sausage gravy or a cherry gouda topping.”

Falek adds, “We created a video that lets you visualize how we bring custom creations to life if you would like to watch.”

Watch just some of the ingredients that are now helping processors create custom flavors.

“Ultimately we are bringing easy, flavorful, on-trend solutions to food manufacturers to reduce their development times and related costs to take new products to market.”

Lucia Falek

VP of Development & Quality Systems

Butterball Farms

From flavored butters to sauces and gravies, Butterball Farms can provide them in a variety of forms including bulk packaging, pails, and portion control. The end use of the products are often heated at home by consumers in ovens, microwaves, air fryers and Instapots.

“Ultimately we are bringing easy, flavorful, on-trend solutions to food manufacturers to reduce their development times and related costs to take new products to market,” says Falek.

Quickly Spin Up Trend-Forward Flavors With Your OWN Twist!

Key to the success of a new product is to predict and act on consumer trends. Whether the focus is on an emerging flavor trend or a spin toward better for you, Butterball Farms actively pursues actionable trends ahead of inquiries from food processors. Here are just a few of the many opportunities to spin up a trending flavor with your own twist that we can support. Contact us to get started!

Elote Is a Super Star – What began on street corners in Spain and Mexico is now center stage. Up 85% on restaurant menus**, elote is America’s fastest-growing comfort food. Food manufacturers and meal kit assemblers can leverage Butterball Farms’ new Elote Dollops as a value-add to their products to easily increase sales. Enclosed in frozen bags of corn for microwaves, ovens, or instapots, elote flavor is now easily done with pre-portioned flavored dollops.

Gravy with Particulate – Gravies are both savory and craveable as a value-add to a product. The most recent innovation in gravies is the inclusion of particulates in country gravy using pieces of sausage. Pre-portioned dollops or medallions can be sized to your specs and can be inserted in biscuits for grab and go sandwich solutions for packaged goods or retail customers. The ability to offer small chunks of sausage within a country gravy is the essence of authenticity and the latest innovation opens the door to other applications beyond gravy such as pieces of bacon in a butter dollop or sundried tomato in a sauce. The gravies can also be provided in tubs or portion-controlled cups.

Garlic Parmesan Beyond Italian Cuisine– An old faithful is a comfort flavor that goes beyond Italian. Snacks, breads, frozen pastas and vegetable products can all be accelerated to market with help from Butterball Farms.

To access a Butterball Farms consultation about your latest product challenge in need of a custom creation, we’re happy to help.

*Food Processing, 51st R&D Survey, 2022